Biological

Category:Biological laboratory test Hits:1090

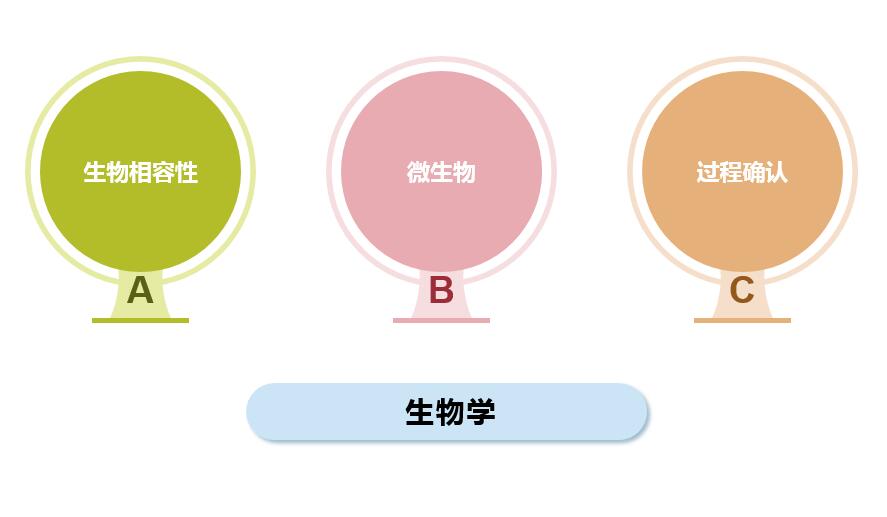

Biocompatibility test

Biocompatibility tests are used to evaluate the appropriate response of a medical device to a specific part of the body and to determine the safety or biocompatibility of the product in a biological environment. Befitlab group provides comprehensive biocompatibility evaluation solutions to medical device enterprises, and provides testing services and product improvement solutions to meet the needs of different stages of design and development, process validation, and preclinical research in the target market.

Biocompatibility testing projects include:

Chemical/physical characterization

Cytotoxicity

Irritation and sensitization

Pyrogen/endotoxin

Genetic toxicity

Implant test

Blood compatibility

Systemic toxicity (acute, subacute, subchronic, chronic)

Carcinogenicity

In vivo/in vitro degradation test

USP 88 Plastic Class VI Testing

Assessment of biocompatibility of respiratory gas pathways (ISO 18562 series)

Microbiological test

For aseptic medical devices, microbiological testing is very important in terms of microbiological control of finished products, production process and environmental control, it includes biological loading, microbial limits, bacterial endotoxin and sterility tests. Befitlab group can assist you in the design of tests for evaluating finished products or manufacturing factors that may affect the ultimate sterility of medical devices.

Microbiological testing projects include:

Biological load

Microbial limit

Bacterial endotoxin

Sterile test

Process to confirm

For the detection of medical devices, manufacturers usually pay attention to the inspection result of the final product, but ignore the possible impact of the production process and the instructions in the instruction manual. This can lead to unexpected performance errors in product quality or risk to patients.

Befitlab group can design suitable tests based on your production process and evaluate the process capability and effectiveness recommended in the production process and the specification to ensure that the requirements of different regulatory bodies such as NMPA, notified bodies and so on.

The confirmation services we can provide for you include:

Cleaning confirmation

Hot and humid sterilization confirmation

Shelf life verification

Clean room environment validation

Confirmation of packaging process

For other special process confirmation, please contact us. We can customize the confirmation plan and carry out relevant tests according to your process